R S Cockerill, located in York, is a leading provider of potatoes for Aldi and Walkers Crisps. As part of their ongoing commitment to safety and compliance, they recently initiated refurbishment works to expand their welfare staff building. To ensure the safety of their employees and contractors, they commissioned an asbestos management survey, which identified asbestos cement roof material on one of the roofs.

Challenges Faced: With the refurbishment project underway, R S Cockerill encountered the challenge of managing asbestos-containing materials (ACMs) within their premises. The presence of asbestos cement roof material posed a potential risk to the health and safety of workers if not properly managed.

Solution Provided: In response to the identified asbestos risk, R S Cockerill collaborated with a Complete Asbestos Surveys to conduct a comprehensive asbestos survey. The survey revealed the presence of asbestos cement material in a safe condition. As a proactive measure, R S Cockerill opted for asbestos management rather than immediate removal.

Implementation Process: The asbestos management plan devised for R S Cockerill included regular inspections, monitoring, and maintenance of the asbestos-containing roof. Additionally, the plan outlined procedures for safe work practices to prevent disturbance or damage to the asbestos material during refurbishment activities.

Benefits for R S Cockerill:

- Compliance Assurance: By adhering to asbestos regulations and guidelines, R S Cockerill demonstrated their commitment to compliance and safety standards.

- Cost-Efficiency: Choosing asbestos management over removal saved R S Cockerill significant costs associated with asbestos removal and disposal.

- Minimized Disruption: The proactive approach to asbestos management minimized disruption to ongoing operations and refurbishment activities.

Conclusion: Through the implementation of an effective asbestos management plan, R S Cockerill successfully addressed the asbestos risk associated with their refurbishment project in York. By prioritizing safety and compliance, they safeguarded the well-being of their employees and contractors while ensuring the smooth progress of their expansion endeavours.

For companies facing similar challenges, proactive asbestos management is key to mitigating risks and maintaining a safe working environment.

Case Study Overview

Location

York

Year

2024

Services Provided

Asbestos Management with Part Refurbishment Survey

More Case Studies

You might also be interested in these…

Law Slack House

Asbestos Management Survey for Law Slack House Client Overview: Complete Asbestos Surveys conducted an asbestos management survey for a client interested in purchasing Law Slack House, an old farm cottage with unique character features. The…

Learn More

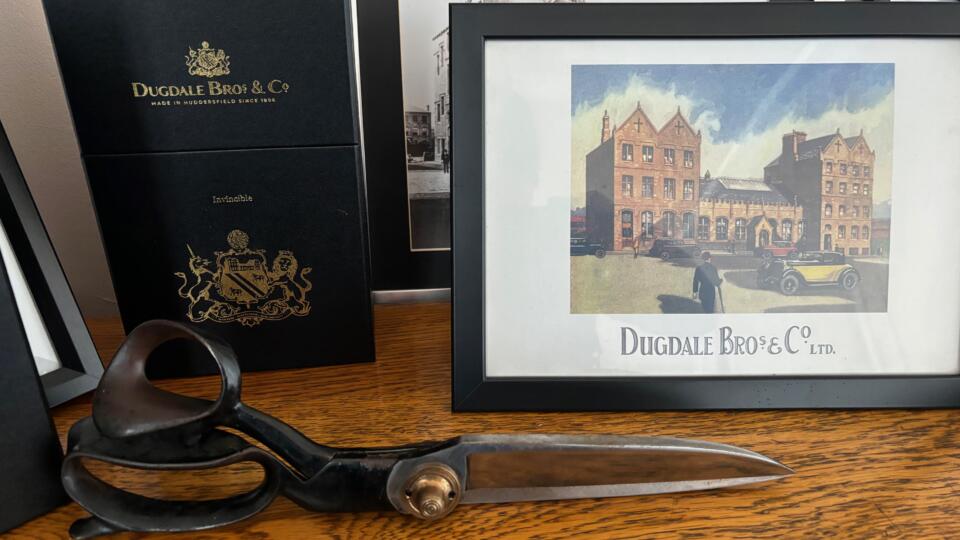

Dugdale Bros & Co Ltd

Dugdale Bros & Co Ltd sought to ensure compliance and safety during a new cable installation project, prompting the necessity for an asbestos survey. During the survey, asbestos paper vapor barrier was discovered on the…

Learn More

Hampden House

Hampden House, nestled in the heart of Withington, Manchester, posed a critical concern for its proprietors, The Retreat Clinics. Aiming to ensure the utmost safety for their occupants, The Retreat Clinics enlisted our services to…

Learn More

Hollands Country Clothing

Hollands Country Clothing, a renowned provider of outdoor apparel, approached us with a crucial concern regarding their property’s safety and compliance. Recognizing the potential hazards associated with asbestos, they sought our expertise to conduct an…

Learn More