HB Bearings is a manufacturer of bearings and other industrial components located in Huddersfield, West Yorkshire. The company has been in operation for over 50 years and employs over 50 people.

HB Bearings commissioned an asbestos management survey to be carried out on its factory premises. The survey was carried out by a Complete Asbestos Surveys who inspected all areas of the factory, including the exterior, interior, and any associated plant and equipment.

Our asbestos surveyor took samples of any suspected ACMs and sent them to a UKAS-accredited laboratory for analysis. The laboratory then produced a report that identified the type of asbestos present in the samples.

Once our surveyor has received the laboratory report, they produced a management survey report.

The following asbestos items were identified in the survey:

- Insulating board ceiling and wall panels

- Asbestos roof sheets

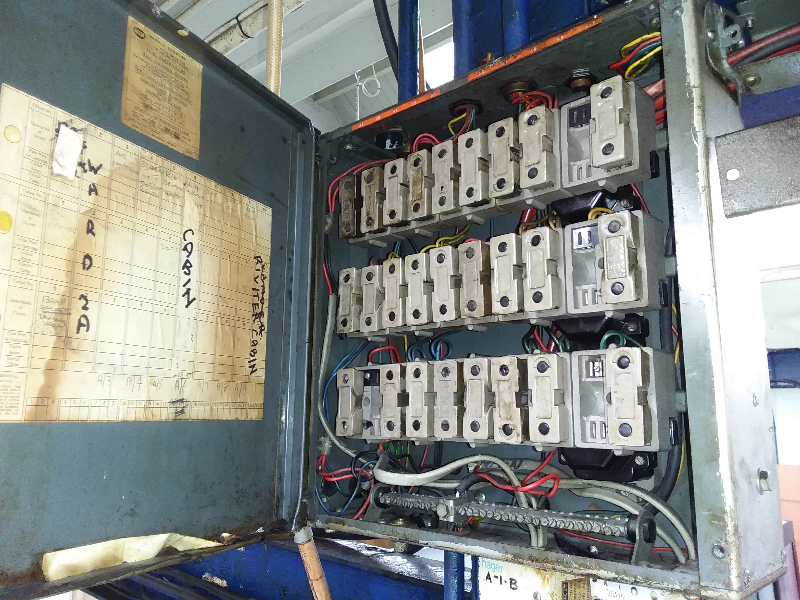

- Woven fuse guards

- Rope seal to windows

The surveyor recommended that the following actions be taken to manage the ACMs:

The insulating board ceiling and wall panels need to be encapsulated and labelled.

All other asbestos containing items need to be labelled and managed.

HB Bearings has accepted the surveyor’s recommendations and is currently in the process of implementing them.

The asbestos management survey at HB Bearings is a good example of how important it is to have asbestos surveys carried out regularly. By identifying and managing ACMs in a safe way, HB Bearings is helping to protect the health and safety of its employees and visitors.

Case Study Overview

Location

Huddersfield

Year

2023

Services Provided

Asbestos Management Survey

More Case Studies

You might also be interested in these…

Law Slack House

Asbestos Management Survey for Law Slack House Client Overview: Complete Asbestos Surveys conducted an asbestos management survey for a client interested in purchasing Law Slack House, an old farm cottage with unique character features. The…

Learn More

R S Cockerill

R S Cockerill, located in York, is a leading provider of potatoes for Aldi and Walkers Crisps. As part of their ongoing commitment to safety and compliance, they recently initiated refurbishment works to expand their…

Learn More

Dugdale Bros & Co Ltd

Dugdale Bros & Co Ltd sought to ensure compliance and safety during a new cable installation project, prompting the necessity for an asbestos survey. During the survey, asbestos paper vapor barrier was discovered on the…

Learn More

Hampden House

Hampden House, nestled in the heart of Withington, Manchester, posed a critical concern for its proprietors, The Retreat Clinics. Aiming to ensure the utmost safety for their occupants, The Retreat Clinics enlisted our services to…

Learn More